Presses for PB, MDF and OSB:

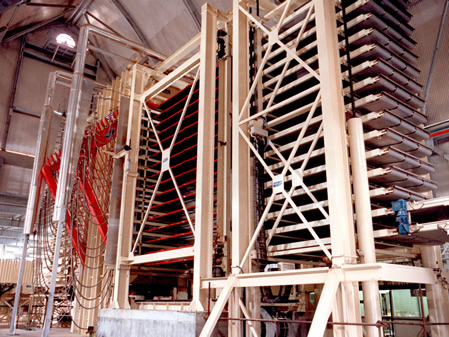

Pagnoni has built a great number of lines with

single, double and multi-opening presses having capacity

output range from 50 up to 1,000 m3/day, thus satisfying

customers’ more different requests in terms of sizes,

thickness and product quality. Among the several

technical innovations introduced by Pagnoni in

this field can be mentioned, the electronic space bars to

control the given board thickness without manual

operations, the new hydraulic circuits to minimize dead

times and to regulate the pressing according to the board

size, and the powerful and sophisticated continuous

pre-compressor.

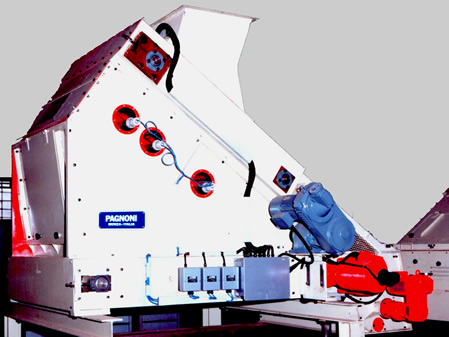

The common denominator of all Pagnoni machinery,

is construction

simplicity, sturdiness and durability: the

Pagnoni manufacturing concept for more than 150 years.

In the field of lines for MDF production Pagnoni has

developed its expertise in designing presses of gigantic

dimensions with massive capacity, up to 1000 m3/day. The

press lines, designed in the latest years, have given the

Company the opening to develop a unique and complete

product line.

Recently Pagnoni has developed the project for OSB press

lines following the market trend and the growing global

demand.

Every new plant benefits from improvements and

innovative technical solutions, allowing Pagnoni to be

listed with the world's limited number of MDF producers of

single and multi daylight presses.

The company's decision not to develop a continuous press

for raw board production, has given Pagnoni the great

opportunity to implement machine technology of single and

multi-opening presses and consequently to enter a market

niche of those producers requiring special product,

of improved properties and value added market access,

almost impossible to obtain with continuous production

lines.